Vertical

Click Title To View Category...

Horizontal

Click Title To View Category...

5-Axis

Click Title To View Category...

Bridge

Click Title To View Category...

Tapping

Click Title To View Category...

Ver

ti

cle

Verticle Milling

Machines

The Industry Workhorse

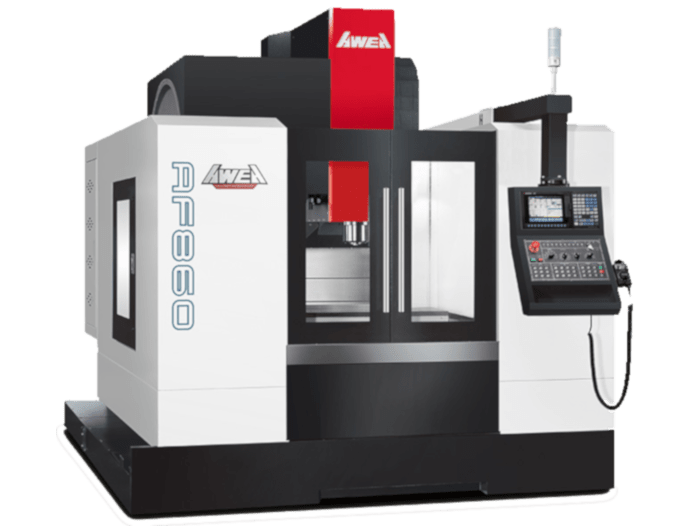

Vertical Milling

— AF Series

Introducing AWEA with mature manufacturing abilities and advanced technology skills, the AF series. They are based on super rigidity structure and three axes high precision linear guide way design with fast arm type ATC and chip conveying system. It is to provide you with fast, strong, stable machining performance. AF series are broadly used in high precision machine parts manufacturers, which can easily meet your demands of today and tomorrow.

Based on AWEA’s innovative technology, the AF series is specialized on high precision parts and mold machining industry. It can fully present high precision and high efficiency machining ability with very reasonable cost.

AWEA in house made gear box spindle provides the best torque combination. Box way on 3 axes to fulfill reliable and stable heavy-duty cutting requirement. Precise hand scraping on key contact surfaces to ensure the best support and consistent machine accuracy.

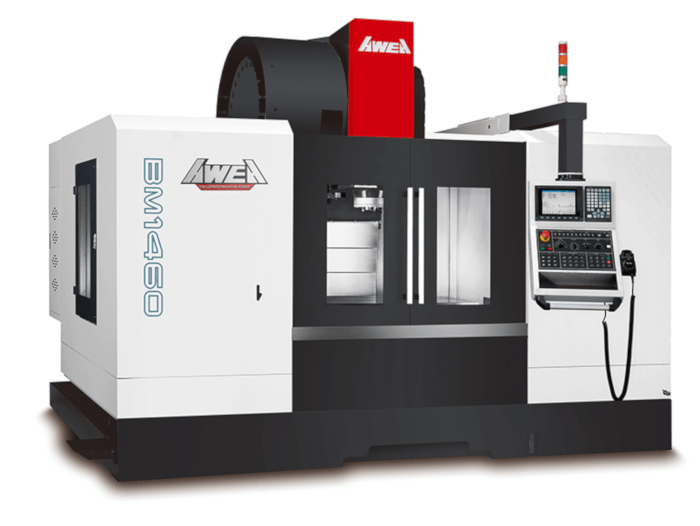

With the advanced R&D technology and strict quality control, BM series is specially made for heavy cutting machining needs, which have rigid and stable machine structure for extensive application. BM series offers excellent performance with reasonable and affordable price.

— BM Series

Vertical Milling

Proven rapid return on investment.Compact – Ergonomic – Powerful – Accurate!

The VX is an ideal investment for the manufacture of tooling and for small to medium-scale production.

Key Features

- C-frame structure in quality ribbed cast iron

- Broad-based architecture with reinforced column to withstand cutting forces and absorb the effects of machining vibrations

- Excellent dynamic performance for rapid changes of direction and acceleration

- Calibrated, pre-stressed ballscrews with direct motor coupling

— VX Series

— KMILL Series

Key Features

- Ribbed cast iron structure offering high mechanical performance for greater rigidity

- Excellent absorption of the vibrations generated by the tough cutting conditions

- Floor anchoring to maintain geometric stability and precision over time

The NX series of flexible, modular three-axis portal milling centres fulfils the most exacting demands in the field of general mechanical and precision engineering. Its portal structure, wide distance between uprights and optimized cutting conditions provide an ideal environment for intense, quality machining of large, heavy and complex parts.

Key Features

- Robust construction and floor anchoring to guarantee precision and geometric stability

- High chip removal capacity on roughing with the friction guiding system on the vertical axis

- Large table area and wide distance between uprights to process the full volume of the workpiece

- Outstanding accessibility to the table and workpiece thanks to the tunnel-type shroud

- Simpler maintenance

— NX Series

Hori

zo

ntal

Horizontal

Machines

Get At It Sideways

Horizontal Machines

— AH Series

Ultra Performance Horizontal Machining Center

The AH series undergoes a stringent inspection process and is the top horizontal machining center in its class, featuring advanced and progressive designs.

- In order to fulfill various working conditions, the machine can be equipped with a 10,000 rpm direct drive spindle or a 705 N-m gear spindle.

- The heavy-duty working table can hold up to 1,200 kgs ( 2,645 lbs ) and only takes 16 seconds to change, effectively increasing production.

- Three axes movement, tool changer, worktable, and other main components are driven by servo motors. This will control the speed of the movement efficiently thereby reducing heat.

- The complete coolant chip removal system consists of two chip augers, chip conveyor and a large volume tank that can remove chips efficiently.

High Rigidity Horizontal Boring Mills

Introducing AWEA with mature manufacturing abilities and advanced technology skills. The BL series combine high rigidity structure, heavy duty load capacity rotary table and a high torque spindle ( BL-S ) or high speed spindle ( BL-FM ) along with our professional assembly and hand scraping skills. BL series can easily overcome most stringent requirements of not only deep hole boring but high precision mold milling which meet your various needs for today and the future.

With years of innovation and manufacturing experience on horizontal boring mills, combined with the latest machining center technology, to maximize the mechanical performance and the brand image as a professional boring mills manufacturer.

— BL Series

5-

a

xis

5-Axis Milling

Machines

Leave Nothing Untouched

5-Axis Milling

— FV-960 Series

Derived from AWEA’s mature R&D technology and manufacturing capability, FV-960 is especially designed for medium and small intricate parts machining. FV-960 is equipped with high efficiency direct drive spindle and strong roller linear guide ways, combines with high performance A / C axes rotary table to provide you high productivity and comprehensive 5 axes cutting solution. FV-960 has the best performance/cost ratio among the 5 axes machines in the same range, which can meets your various needs for today and tomorrow.

Aerospace

High precision, high complexity parts machining requirement

Automobile

High precision, high stability parts machining requirement

Biomedical and Health Equipment

High efficiency, difficult cutting materials machining requirement

Ultra Performace 5-Axis Machining Center

Derived from AWEA’s advanced R&D technology and high quality components, FCV series 5-axis machining center offers high speed, high accuracy, easy operation and many other superior capabilities. FCV series is having best performance costratio than any other same class models in the field of the 5-axis machining center.

- Outstanding 5-axis simultaneous machining ability can finish complicated parts in a single setup which especially suits automobile, aerospace, medical and other industries that needs of high accuracy.

- High Performance B / C-axis rotary working table. Table load capacity is up to 300 kg ( 0˚ ~ 45˚ ). B-axis swiveling range is -50˚ ~ +110˚ .

- Depend on different machining characteristics, FCV series provides 12,000 / 15,000 rpm direct drive spindle or 16,000 / 20,000 rpm high speed built-in spindle.

— FCV-620 Series

— AG-5 Series

Gantry Type High Speed 5 Axes Machining Centers

Gantry type rigid structure

• 40% less floor space required compared to other bridge type machines with similar travel ranges.

• All axial movements are executed by the cutting tool instead of the work-piece, causing less load on the axes and thus improving dynamic accuracy.

High performance B/C two axes head

• ITALIAN made two axes head designed for high performance & high stability.

• A variety of milling heads are available optionally – high rotation speed / high torque / compact structure.

Environment-friendly technology• The GERMAN made hydraulic unit requires only 20% of the space ordinary hydraulic units occupy. It uses up to 90% less electricity than traditional hydraulic units, thus significantly reducing running costs.

5-Axis Mlling

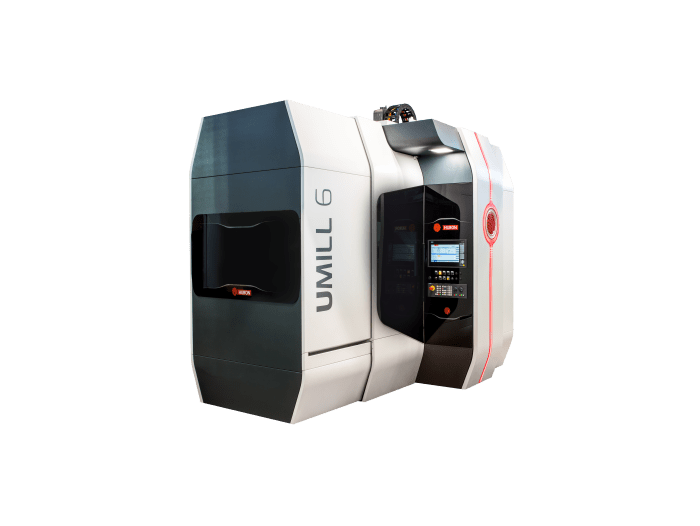

—Umill Series

Umill range is a 5-axis machining centres with a portal structure and a swivelling rotary table on cradle. Its modern design and compact size are optimized to guarantee a minimal footprint without compromising either to the workpiece volume or to the fundamental caracteristic of the HURON machines : enhanced rigidity for high performance and quality machining. This range is ideally suited for complex parts in 3 or 5 axes, from roughting to finishing, for various sectors such as high precision mechanical parts, automotive, rail, energy, machining of 3D forms, or aerospace.

Key Features

- structure with fixed portal in ribbed cast iron with stiffness walls attenuate the torsional stresses

- modular design allowing maximum flexibility in machine configurations

- swivelling rotary table fixed on cradle

- optimized travels to offer an important distance under the spindle nose

The KX Five series is a combination of dynamics and precision for continuous five-axis machining of complex parts. Through the excellent standard of machining vibration damping, high-quality surface finishes and optimum precision can be achieved on a variety of materials.

Key Features

- Large-sized monoblock bed and reinforced portal

- Guiding system for the headstock, saddle and table providing high stability during movement

- Continuously controlled two-axis table

- Floor anchor points guaranteeing optimum speeds and acceleration

- Compact machine

— KX Five Series

— KX Large Series

The KX Large Series offers a wide selection of machines for continuous five-axis/five-side machining of complex parts.The fixed-portal architecture and machine design ensure maximum rigidity for extremely precise machining in a variety of difficult materials.

Its large work area, capable of supporting up to 20 tonnes in weight and accomodating processable volumes up to 4.080 x 2.180 x 1.550 mm, is suited to machining large parts for general mechanical and precision engineering, 3D shapes, and the aeronautical and energy sectors.

Customer reguirements are comfortably met by the modularity of design, the choice of variants, and equipment.

Key Features

- Machine with palletizing function for increased productivity

- Volumetric precision for making moulds and complex parts

- Spindle offering optimum performance for roughing and finishing

- Structural design guaranteeing long mechanical life

- High degree of precision due to direct measurement on the linear and rotary axes

Br

id

ge

Bridge Milling

Machines

BRIDGE The Gap

Bridge Milling

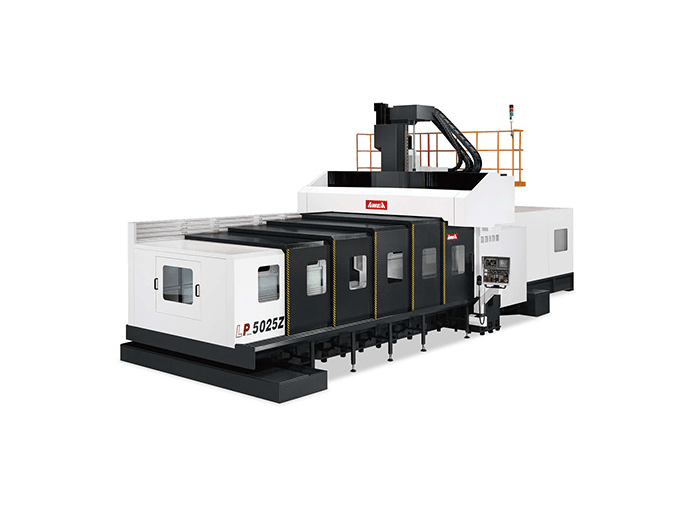

— LP Series

Ultra Performance Bridge Type Vertical Machining Center

Representing AWEA’s “The royal family of bridge machines” of mature manufacturing abilities and advanced technology skills, the SP and LP series bridge type vertical machining centers combine strong spindle power and high rigidity structure along with high quality automation equipments and full product line to provide you with high efficiency, high productivity machining strategies; it can be broadly applied in the automotive, precision mold, aerospace and energy industries., etc.

The LP series can be equipped with an automatic head changer and vertical / horizontal ATC system which turns into a 5-face machining center providing more cutting flexibility to meet your demands of today and tomorrow.

Cross Rail Bridge Type 5-face Machining Center

Packed with AWEA’s industry leading technology and high quality components, the MVP series double column bridge type 5-face machining center gives you automatic multi-face cutting power with maximum working range. Combined with rock-solid cross rail construction ( W-axis ), these series is provided with 49.2″ ( 1,250 mm ) large W-axis travel, 39.3″ ~ 55.1″ ( 1,000 ~ 1,400 mm ) Z-axis travel, any-position automatic horizontal / vertical tool changer, and automatic optional heads exchange to fulfill all your work needs for today and tomorrow.

- The working table is fully supported with 4 heavy duty guide-way rails. ( linear guide ways x2, Box way x 2 )

- It is heat-treated and precise scraped with maximum loading up to 39,600 lbs. ( 18,000 kg – MVP-5032 )

- High efficient servo tool magazine can horizontally / vertically change tool at any position in the W-axis which greatly decreases non-cutting working time.

- The bed, columns and cross rail are adopted with high rigidity box structure design and applied with prolonged annealing process to assure a firm construction for high machining precision.

— MV-5032 Series

— AG-5 Series

Gantry Type High Speed 5 Axes Machining Centers

Gantry type rigid structure

• 40% less floor space required compared to other bridge type machines with similar travel ranges.

• All axial movements are executed by the cutting tool instead of the work-piece, causing less load on the axes and thus improving dynamic accuracy.

High performance B/C two axes head

• ITALIAN made two axes head designed for high performance & high stability.

• A variety of milling heads are available optionally – high rotation speed / high torque / compact structure.

Environment-friendly technology• The GERMAN made hydraulic unit requires only 20% of the space ordinary hydraulic units occupy. It uses up to 90% less electricity than traditional hydraulic units, thus significantly reducing running costs.

Tap

pi

ng

Drill/Tapping

Machines

TAP It

Drill/Tap

— AT-510 Series

High Speed Drilling & Tapping Center

Based on the technical foundation of AWEA excellent quality vertical machining centers, AT-510 high speed drilling and tapping center is designed for automobile, electronic industry, and etc., providing with high speed, high precision, and high stability processing feature. AT-510 is having the best performance / cost ratio among the machining centers in the same range, which can meets your various needs for today and tomorrow.

High speed, high accuracy, low vibration direct drive spindle design, providing 12,000 / 15,000 / 20,000 rpm spindle speed to fulfill variety of precision processing requirements. High Performance ATC system with synchronous unclamping type tools changer provides fast and steady tool change capability.

Drill/Tap

—Tachyon Series

These machines combine dynamism and accurate precision machining. They are perfectly suited to production lines in series

Key Features

- Machine with reduced footprint

- Fixed bed structure with traverse, saddle and mobile spindle carriage for high dynamics and accurate machining

- Fixed structure and 3 linear axes on tools to allow high rigidity and dynamism

- Integrated divided table with rapid rotation to reduce the workpiece changing time